The heart of your heating system … where warmth begins.

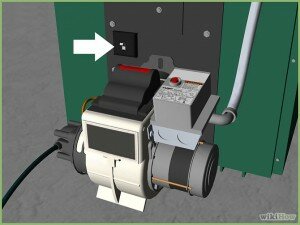

An oil burner has these key characteristics:

- An electric motor that drives the fan and fuel pump.

- The fan pushes air to the burner’s air tube to support combustion.

- The pump draws oil from the tank and delivers it to the nozzle.

- The regulating valve, located in the pump housing, produces the right amount of pressure to atomize the oil.

- The ignition/transformer produces a high-voltage spark that provides enough heat to vaporize the atomized oil from the nozzle and achieve ignition.

- The drawer assembly holds the nozzle and electrodes.

and mixed with air before it can burn. When the oil from the

storage tank reaches the burner’s nozzle, it’s broken into

small droplets. This process is called atomizing.

These droplets are mixed with air and then

by a burner depends on its design. The biggest difference

between old burners and modern ones is the

air handling step of the process.

Flame Retention Burner

In the late 1960s, the manufacturers of Oilheat equipment introduced the flame retention burner, which produced a smaller, more compact flame. Since its advent, the high-efficiency flame retention burner has saved homeowners billions of dollars in fuel costs. More than six billion gallons of fuel have been conserved. The flame retention burner has also helped reduce emission levels of oil-fired heating systems to almost zero. Compared with older burners, the flame retention burner:

- Burns cleaner.

- Has an efficiency level that’s 5% � 15% higher.

- Produces a hotter flame.

- Maintains an airflow pattern that results in a more complete mixing of fuel and air.

The flame retention burner gets its name from the compact

The flame retention burner gets its name from the compactflame it produces as illustrated in the diagram above.

Older burners produce a less controlled, less efficient

flame as shown in the diagram below.

Clean Burning

The newest burners for Oilheat systems make home heating with oil cleaner and more environmentally friendly than ever before. Advancements in Oilheat technology have made Oilheat 95% cleaner than it was 25 years ago1.

The newest burners for Oilheat systems make home heating with oil cleaner and more environmentally friendly than ever before. Advancements in Oilheat technology have made Oilheat 95% cleaner than it was 25 years ago1.

- Modern oil burners use electronic pre-purge and post-purge controls that ensure ultra-clean starts and stops. The high static air pressure produced by the burner helps prevent particle buildup.

- Achievements in oil burner technology have resulted in emissions levels approaching zero.2

- The oil burners of today are so clean that they produce on average six ounces of particulate emissions (or soot) a year. To put that in context, consider that the six ounces of emissions comes from burning three tons of heating oil.

- Oilheat burns so clean that there are no federal regulations.